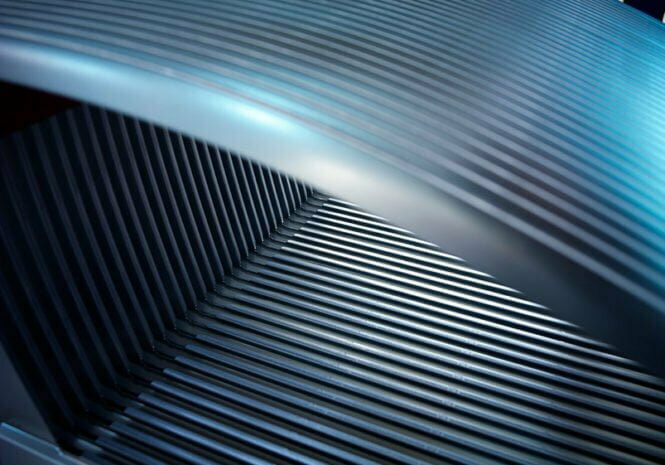

(Credit: Novelis)

(Credit: Novelis)Novelis, a sustainable aluminum solutions provider, has announced a strategic partnership with Sortera Alloys, an industrial scrap metal sorting and recycling company. Novelis will take advantage of Sortera's sorting technologies, including data analytics and sensors, to recycle and reuse higher amounts of both automotive post-production and post-consumer scrap.

Today, when different aluminum alloys are mixed, either after the automakers' stamping process or when a vehicle is disposed of at the end of its lifecycle, they cannot be re-separated into the individual alloys. As a result, the higher value alloys are downgraded into lower value uses. With the use of the Sortera technology, Novelis will be able to effectively separate the mixed scrap into individual alloys and recycle them back into the same product, closing the loop. This will allow Novelis to meet original equipment makers' exacting needs for performance, durability, safety and design.

Novelis says the partnership supports the company’s sustainability goals to reduce its carbon footprint by 30% by 2026 and to be carbon neutral by 2050 or sooner. Using recycled aluminum as input material requires approximately 5% of the energy used to make primary aluminum, thus avoiding approximately 95% of the carbon emissions associated with production.

"Our partnership with Sortera will allow Novelis to continue to increase the amount of recycled content in our automotive alloys and subsequently reduce our carbon footprint," said Derek Prichett, Senior Vice President, Corporate Development at Novelis. "It also aligns with our goal of becoming a fully circular business, as we will be able to keep more automotive aluminum in our supply chain and redirect it back into the same products."

The aluminum industry as a whole is responsible for 2% of the world’s man-made GHG emissions and emits more than 1 billion tons of carbon dioxide, due mainly to the electricity required to produce primary aluminum. Demand for aluminum continues to grow as an enabler of the mobility, energy and circular economy transition.

Novelis is also building a $2.5 billion aluminum recycling and rolling plant with a focus on advanced sustainability and circular manufacturing.

The plant is being constructed in Bay Minette, Alabama, and will have an initial capacity of 600,000 metric tons of aluminum products per year. Novelis says more than half the facility will be dedicated to meet growing demand for aluminum beverage can sheet in North America to supply sustainable packaging; the rest of the facility will be geared toward vastly increasing the company’s recycling capabilities.