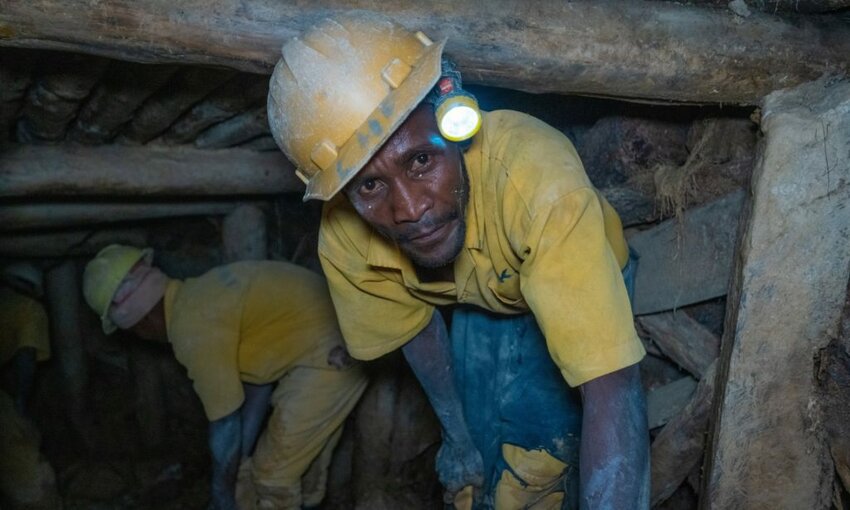

(Photo: A worker inside a tin mine run by the Comikagi cooperative near Nyamugali, Rwanda. Credit: Walden Kirsch/Intel Corporation)

(Photo: A worker inside a tin mine run by the Comikagi cooperative near Nyamugali, Rwanda. Credit: Walden Kirsch/Intel Corporation)Intel says that a fact-finding trip to Rwanda is helping the semiconductor company understand their complex mineral supply chain, and go beyond addressing conflict minerals to achieving responsible sourcing.

Consumers and, increasingly, investors want reassurance that companies are responsible corporate citizens. Part of that means rooting out human rights abuses from their supply chains.

Adam Schafer, Intel’s director of supply chain sustainability and Erin Mitchell, manager of Intel’s Responsible Minerals Program, visited six mines and refining facilities in Rwanda last December, the company said this week. The minerals tin, tantalum, tungsten and gold — 3TG — that the silicon manufacturing industry relies on are mined in this part of Africa.

“In chip manufacturing, for example, tantalum is a metal uniquely well-suited as a diffusion barrier on advanced copper interconnects,” Intel said. “In the assembly/test process, tin offers a low melting point and is a key component of the solder that attaches silicon chips to their packaging. Gold is corrosion-resistant and an excellent electrical conductor for the tiny pins that connect chips to other components.”

More than a decade ago, the company realized that some of the minerals it was purchasing through a complex supply chain involving intermediaries were actually conflict minerals. These purchases “were unintentionally contributing to human rights abuses in the Democratic Republic of Congo,” Intel found.

The company made changes, including launching a multiyear industrywide effort to address human rights abuses in the global mineral trade, supporting the US Dodd-Frank Act, becoming a member of the Responsible Minerals Initiative, and announcing plans to ensure that all new processors would be sourced from conflict-free minerals.

During the trip last year, Schafer and Mitchell learned that townspeople were sneaking onto one mine’s property, digging up tin ore, and selling it to buyers in the streets of the capital, undercutting the legal business, according to Intel.

To ensure responsible sourcing, the industry relies on a “bag-and-tag” system, where each bag of mineral ore gets a crimped-on, tamper-resistant tag indicating that it was dug legally by workers on the mine company’s payroll, Intel explained online. The bags are then locked inside a shipping container that also contains a logbook documenting all mineral movements.

Next, the Intel team said they want to figure out a way for artisanal miners to join the process legitimately, helping local residents support themselves and their families while reducing the risk of human rights abuses. The company also wants to expand their strategy beyond the 3TG minerals to the rest of the periodic table.

Intel said that representatives from Apple, Facebook, Google, Nokia and other companies accompanied the team on several mine and government visits in Rwanda. “It’s important that we continue to work with our peers and customers to help make our industry even better,” Schafer said.